Automatic Coordinate CNC Video Measuring Machine AMQ430 Marble

Structure

AMQ430 Marble structure CNC Video Measuring Machine coordinate

measuring equipment

Applicable scope:

This measuring instrument can be used for dimensional accuracy

measurement of various Aerospace, automobile and ship, scientific

research and teaching, electronics, hardware and plastic, precision

metal stamping plate, screen printing plate, acrylic plate, LCP

film, PCB board, LCDTFT, glass cover plate, TP, frame of

ultra-large LCD, die cutting, backlight module group, as well as

for auxiliary measurements such as reverse engineering graphic R &

D, design, drawing editing, laboratory inspection, etc.

Technical parameters

Paramter and Model | AMQ430 |

Workbench | Platfom size(mm) | 560X460 |

Glass table size(mm) | 450X350 |

Weight limit (kg) | 30 |

Travel | X axis(mm) | 400 |

Y axis(mm) | 300 |

Z axis(mm) | 200 |

Image and measurement system | Display resolution(mm) | 1/0.5(Optional) |

Instrument precision(um) | (3+L/200)um |

Imaging system(CCD) | HD color |

Zoom objective(X) | Zoom objective 0.7~4.5X |

Total video magnification(x) | 30~190X |

Working distance(mm) | 96mm |

Light source | LED programmable partiton light source(Coaxial light source

optional) |

Outline dimension(mm) | 870X710X1680 |

Weight(kg) | 450kg |

Power supply | 220V AC 50Hz |

Configuration List:

Sequence number | Name | Unit | Quantity |

1 | Main body | PCS | 1 |

2 | Instrument table | PCS | 1 |

3 | AUSKY software | PCS | 1 |

4 | video card | PCS | 1 |

5 | Joystick | PCS | 1 |

6 | Dongle | PCS | 1 |

7 | Computer | PCS | 1 |

8 | Liquid crystal display | PCS | 1 |

9 | Aocheng optical calibration block | PCS | 1 |

10 | Precision probe(optional) | PCS | 1 |

11 | Keyboard and mouse | PCS | 1 |

12 | Specification warranty card certificate | PCS | 1 |

Introduction to the software functions:

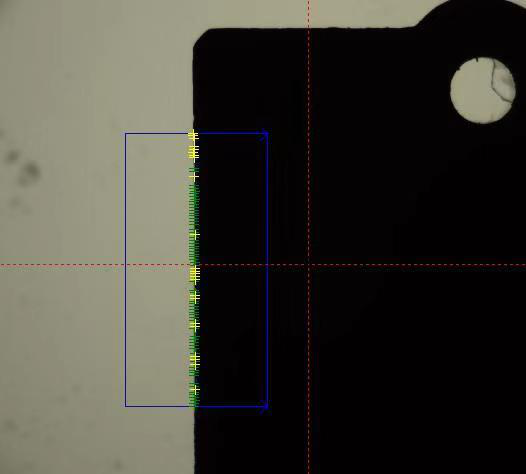

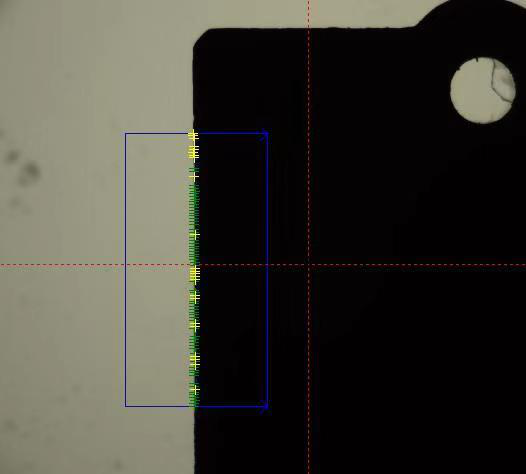

Software interface

1. Multiple measuring methods, including auto edge-tracing, auto

sectional edge-tracing, mouse on-screen point fetch, crossline

pointing, proximity pointing, contrast and pinnacle pointing,

contour pointing, probe pointing, laser pointing, and etc.

2. Powerful edge-tracing algorithm ensures sampling point accuracy

and automatic pixel correction on sampling stability,

where, one stroke will enable automatic pixel correction, needless

to shift frequently.

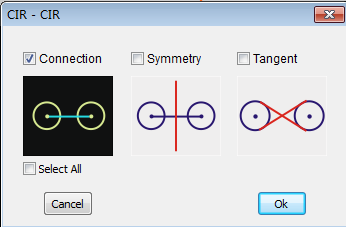

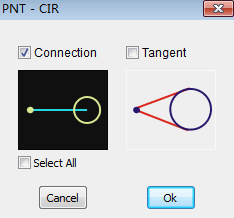

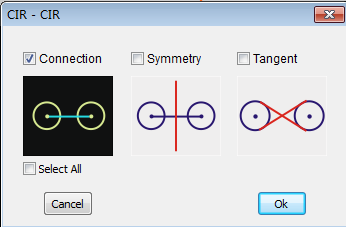

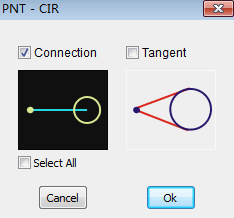

3. Element construction

Element structure technique, offers multiple methods, such as

shifting, rotating, extracting, combining, paralleling,

plumbing, mirroring, symmetry, intersecting, tangentially

structured elements; Element structure will enable user to

tackle some elements hard to measure, and consequently resulting in

increased working efficiency; The compositional

process is to select elements for compositional involvement, select

the result element, clear and simple. Options for

composition methods available in form of illustration.

4. Powerful tagging function

Available in multiple tagging types, for example, tagging of

Distance, Angle, X Distance, Y Distance, Radius, Diameter,

Arc Length, and etc., allows to change position after tagging is

finished, as well as to automatically tag user, that will

remain after program is over.

5. Probe measuring

Powerful functions of software probe measuring enable to character

2D & 3D elements such as height, plane, cylinder,

cone, sphere, ring, etc., and support multiple methods for

establishing 3D coordinates system, with rapid and efficient

programming.

6. Composite measuring of probe and image

Composite measuring by complementing probe with image optical

system achieves multi-purpose measuring of image

and probe.

7. Workpiece array and array macro function

Such function is applied in automatic image measuring instrument.

When a bunch of identical workpieces are placed and

literally equally spaced on one measure fixture, measure one of the

workpieces at first, before measure all the

workpieces on the measure fixture. This will not only save the time

for edge-tracing measuring, but also simplify the

user program.

8. Laser measuring

Laser measuring sees an increasing popularity in imaging device

measuring. Our software is also improved and

optimized responding to the measuring call. We herein introduce as

below:

9. Connection and interfacing with laser

Currently, our measuring device can connect with laser of following

brands: Keyence, Panasonic, Omron, Miyi, Stil,

ERT, Sunny, and etc. Select the laser and COM you wish to connect

with in the Laser List in the Parameter Setting.

(After connection, the measuring method using laser measuring is

indicated as below(L: Reading of the line is the

current laser reading, and corresponding interface of laser

measuring will also pop up in the Graphic Zone)