High Precision CNC Video Measuring Machine 2.5D Image For Aerospace

Electronics

Mechanism and Application Characteristics of Coordinate measuring

machine:

1. Construction of the instrument:

Designed with workbench of a marble panel base and gantry

mechanism, the instrument is characterized by steady accuracy, good

adaptability to working environment, simple, strong, non-deformable

and good-looking body structure, and ergonomically designed

operating mechanism, and meanwhile is equipped with powerful

measuring software and is easy to operate.

2. Movement of Mechanism:

This measuring instrument is provided with tri-axial automatic

control and equipped with import precision Nidec patch grating

system, Japan Panasonic servo high-efficiency motor system, Taiwan

TBI screw rod, Taiwan HIWIN high-precision guide rail as well as

professional measuring software for measurement.

3. Merits with auto-measuring instrument:

This instrument can avoid human error of the “Object Work Piece” as

caused by manual measuring, and can as well avoid secondary damage

caused to “Object Work Piece” by manual measuring, with ensured

mass stability and criteria consistency of the object work piece.

This instrument can enhance multi-fold the detecting efficiency in

the production process, identify the defects and control over

non-yields beforehand in production process, and can meanwhile help

lower part of the costs spent on manual detection, and increase the

timeliness of product delivery.

4. Applicable scope:

This measuring instrument can be used for dimensional accuracy

measurement of various Aerospace, automobile and ship, scientific

research and teaching, electronics, hardware and plastic, precision

metal stamping plate, screen printing plate, acrylic plate, LCP

film, PCB board, LCDTFT, glass cover plate, TP, frame of

ultra-large LCD, die cutting, backlight module group, as well as

for auxiliary measurements such as reverse engineering graphic R &

D, design, drawing editing, laboratory inspection, etc.

5. Main functional configurations of instrument:

This instrument is used in with AUSKY professional automatic

measurement software, Aotian special controller,MEAN WELL power

supply, Panasonic servo motor drive system, TEO color 650TV CCD,

PMS high resolution of 0.7–4.5 folds special high-definition Auto

zoom and fixed-focus screen optical lens, LED partition

program-controlled light source, import precision Nidec patch

grating system, Lenovo computer,LCD monitor,keyboard, mouse, and

the digital measurement.

6. Overall Merits:

A. Suitable for measuring applications of multi-variety, complex

dimensions and demanding measuring accuracy, with even easy and

quick measuring efficacy and enhanced measuring efficiency.

B. The instrument has the following merits with regard to image

processing: automatic burrs skip-over, auto generating measurement

reports and results statistics, and open for linking to printers,

etc., suitable for wide industry applications.

7. Saving cost:

This instrument can achieve multiple functions on the same set of

equipment, resulting in saved user costs for repeated purchasing of

measurement devices as well as saved labor costs and equipment

occupation space. It can meet the needs of user enterprises for

greater development in the future and the demand for rapid

expansion of product testing to lay sound foundation for users’

quality assurance.

Technical parameters

| Paramter and Model | AMH1210 |

| Workbench | Glass table size(mm) | 1300X1048 |

| Weight limit(kg) | 30 |

| Travel | X axis(mm) | 1000 |

| Y axis(mm) | 1200 |

| Z axis(mm) | 200 |

| Image and measurement system | Display resolution(mm) | 1/0.5(Optional) |

| Instrument precision(um) | (4+L/200)um |

| Imaging system(CCD) | TEO HD color |

| Zoom objective(X) | Zoom objective 0.7~4.5X |

| Total video magnification(x) | 30~190X |

| Working distance(mm) | 96mm |

| Light source | LED programmable partiton light source(Coaxial light source

optional) |

| Outline dimension(mm) | 2090X1630X1800 |

|

| Weight(kg) | 2500kg |

| Power supply | 220V AC 50Hz |

Configuration List:

| Sequence number | Name | Unit | Quantity |

| 1 | Main body | PCS | 1 |

| 2 | Instrument table | PCS | 1 |

| 3 | AUSKY software | PCS | 1 |

| 4 | video card | PCS | 1 |

| 5 | Joystick | PCS | 1 |

| 6 | Dongle | PCS | 1 |

| 7 | Computer | PCS | 1 |

| 8 | Liquid crystal display | PCS | 1 |

| 9 | Aocheng optical calibration block | PCS | 1 |

| 10 | Precision probe(optional) | PCS | 1 |

| 11 | Keyboard and mouse | PCS | 1 |

| 12 | Specification warranty card certificate | PCS | 1 |

Introduction to the software functions:

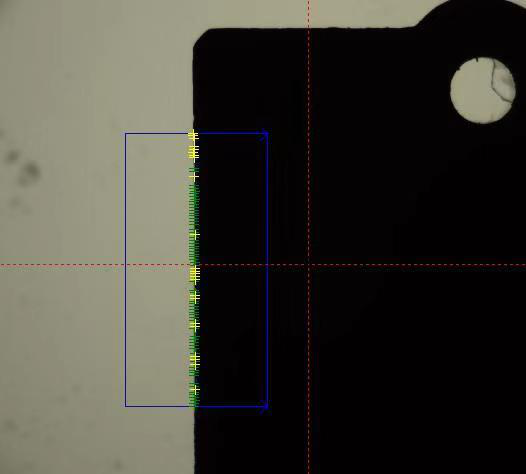

Software interface

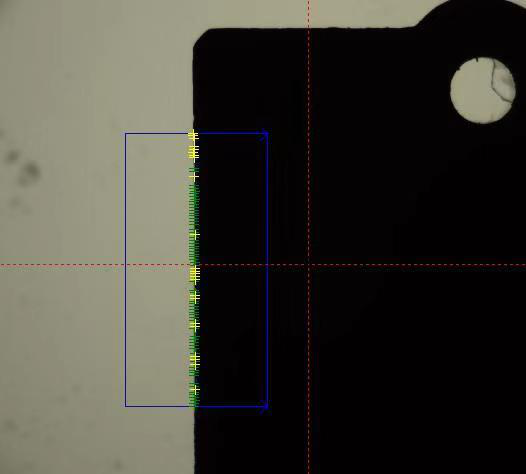

A. Multiple measuring methods, including auto edge-tracing, auto

sectional edge-tracing, mouse on-screen point fetch, crossline

pointing, proximity pointing, contrast and pinnacle pointing,

contour pointing, probe pointing, laser pointing, and etc.

B. Powerful edge-tracing algorithm ensures sampling point accuracy

and automatic pixel correction on sampling stability,

where, one stroke will enable automatic pixel correction, needless

to shift frequently.

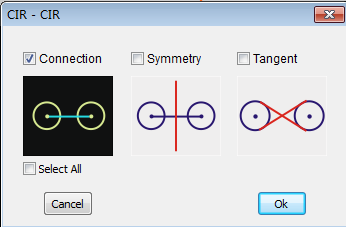

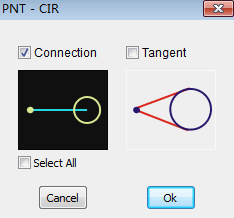

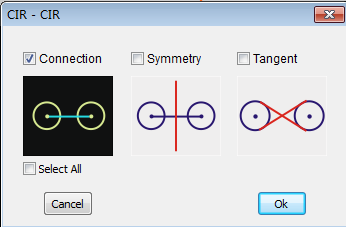

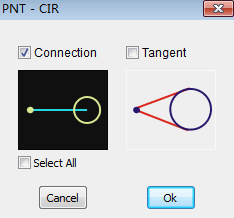

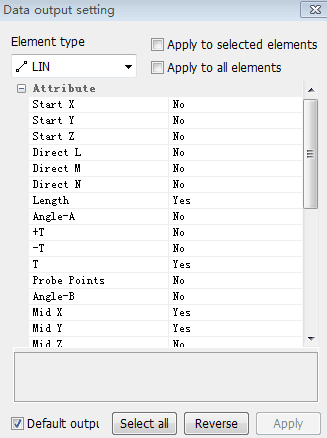

C. Element construction

Element structure technique, offers multiple methods, such as

shifting, rotating, extracting, combining, paralleling,

plumbing, mirroring, symmetry, intersecting, tangentially

structured elements; Element structure will enable user to

tackle some elements hard to measure, and consequently resulting in

increased working efficiency; The compositional

process is to select elements for compositional involvement, select

the result element, clear and simple. Options for

composition methods available in form of illustration.

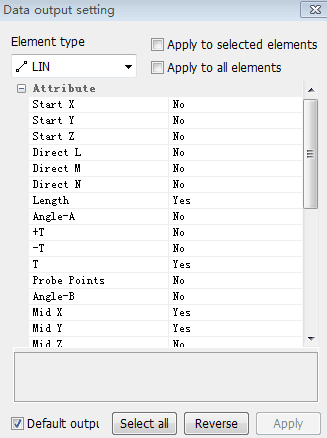

D. Ample report functions

E. Red out-of-tolerance warning

In case of out-of-tolerance of the measuring result, the specific

element and item of element can be displayed, and the

derived EXCEL may the same prompt which item is out of the

tolerance.

F. Ample functions of the image window

Can display magnification ratio and scale, and can do simple

distance and angle measuring

G. Ample functions of coordinate system

Can establish multiple coordinate systems on the basis of the

actual circumstance, can switch flexibly data under all

coordinate systems, can achieve conveniently switchover between

straight angle coordinate system and polar coordinate

system, can achieve the save and call-out of different coordinate

system, and can display different modes of coordinate system.

FAQ

1. How to Choose the Appropriate Specification

As long as you tell us variety and size of product to be measured,

our professional team would advise you

of measuring instrument of suitable specifications.

2. What is the delivery term of your products?

For instruments of general specifications, we have stock ready for

sale. For instruments of bigger sizes

(larger than 1000mm), we can discuss and determine on the concrete

delivery time, which is generally,

3-5 working days after receipt of the payment. However, if you are

in urgent need, we can have the prioritized

consideration for you.

3. Do you accept customized service?

Yes sure! We can provide not only routine machines, but also the

machines customized to customer’s needs.

Please tell us your concrete requirements, we would come out with

designplan tailored exclusively for you.

4. What is your warranty period?

Our product warranty period is one (1) year. Our product quality is

very stable, You can rest assured of our product quality.

5. Have you ever had clients in our country before?

Our equipment has been widely sold to Malaysia, UK, Italy, Germany,

India, Pakistan, Philippines, Singapore,

Thailand and Vietnam, Korea, USA, Poland, Russia,

Turkey,Mexico,Israel.