One Button Fast Vision Measurement System Real Time Image Display

Energy Saving

Technical parameters:

| Model and parameter | AMO150 |

| The camera | 5 million 2/3 inches, 12 million 11.1 inches, 20 million 1 inches

optional |

| Light source | According to the purpose of measurement,optional parallel bottom

light, telecentric bottom light, 1-8 partition ring light, coaxial

light ,etc |

| Repeatability(±μm ) | 1.5μm |

| Instrument precision(±μm ) | 3μm |

| 100 Element Measuring Time (s) | 0.2s |

| Load-bearing weight(KG) | 20KG |

| Outline dimension(mm) | 450x580x1900 |

Configuration List:

Number | Name | Unit | Quantity |

1 | Main body | PCS | 1 |

2 | AUSKY software | PCS | 1 |

3 | Dongle | PCS | 1 |

4 | Private Computer Host | PCS | 1 |

5 | Liquid crystal display | PCS | 1 |

6 | AUSKY optical corrector | PCS | 1 |

Introduction of Software System

Main features:

a. Complete image metrology software functions: including the

measurement of all kinds of 2D element points, lines, circles,

arcs, Polylines, spline curves;

b. Complete coordinate system, structure and tolerance calculation

function;

c. The function of importing and exporting CAD and offline

programming;

d. High-precision sub-pixel interpolation and lens distortion

compensation function;

e. Target recognition and image matching module (optional function)

f. In collaboration with other professional machine vision

companies, we take the lead in introducing advanced functions such

as general machine vision algorithm, image preprocessing, mosaic,

morphology, miscellaneous edge and weak edge recognition, gray

level variance, color difference discrimination, image template,

Blob, bar code, outline recognition and comparison in metrology

software; (Optional function)

g. Motion measurement module: supports on-line measurement-level

high-precision detection of moving objects. (Optional function)

The main functions of the software are as follows:

1. Image measurement tools

Specifically, it includes the following functions:

Import static pictures

Import static pictures

Save pictures

Save pictures

Field of view zooming

Field of view zooming

Field of View Adaptation

Field of View Adaptation

Camera Dynamic Preview and Image Capture

Camera Dynamic Preview and Image Capture

Setting of Measuring Parameters

Setting of Measuring Parameters

Point Cloud Tool

Point Cloud Tool

Automatic Recognition of Objects and Spline Curve Circle Measuring

Tool

Automatic Recognition of Objects and Spline Curve Circle Measuring

Tool

Linear measuring tool

Linear measuring tool

Circular measuring tool

Circular measuring tool

Arc measuring tool

Arc measuring tool

Point measuring tool

Point measuring tool

Extremum Measuring Tool

Extremum Measuring Tool

Rectangular Range Definition Tool

Rectangular Range Definition Tool

2. Control tools:

Through the above tools, such as delay, input, output, circulation,

light source, camera and so on, it can realize linkage with

external PLC controller, manipulator, conveyor belt, switch,

induction device, light source, camera, alarm indication, etc.

Quickly build online automation application scenarios.

3. Element Attribute Page:

Element attribute pages are used to display the results and

attributes of program items, measurement elements, construction

elements, calculation tolerances, hardware controls, etc. Batch

output settings and tolerance definitions of tolerances within

batch elements (X, Y, Z, R, D, Form) can be made.

Note: Form tolerance supports straightness, roundness, flatness and

curve contour.

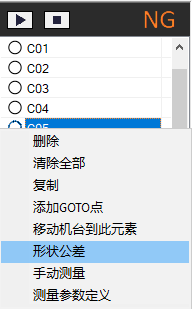

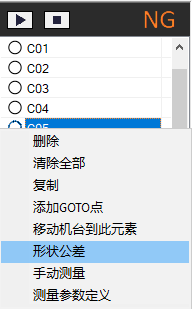

4. Program list area:

The program list area has the functions of recording and managing

user programs, editing, inserting, deleting, modifying program

parameters, executing, stopping and displaying program execution

results through the right-click menu.

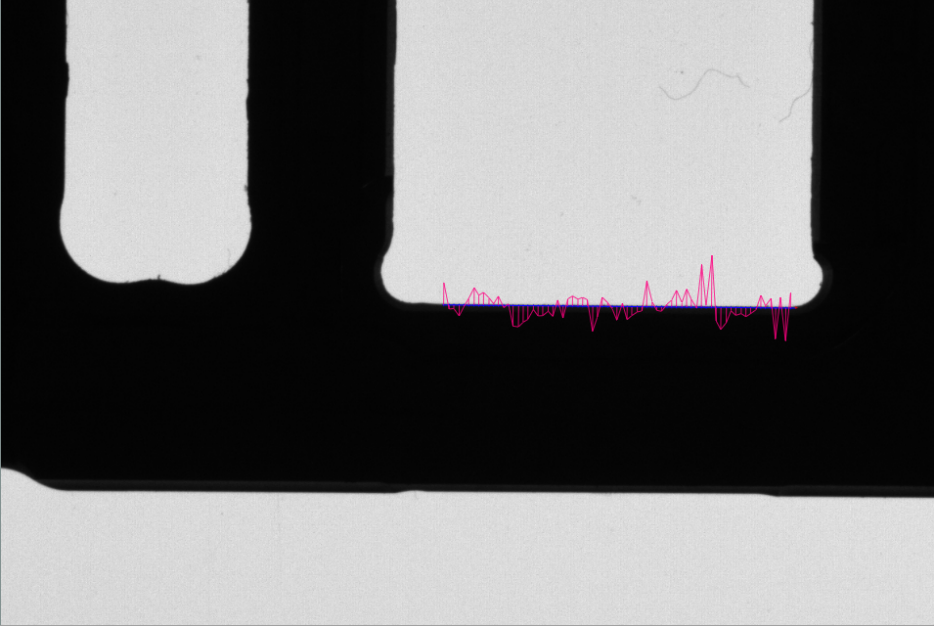

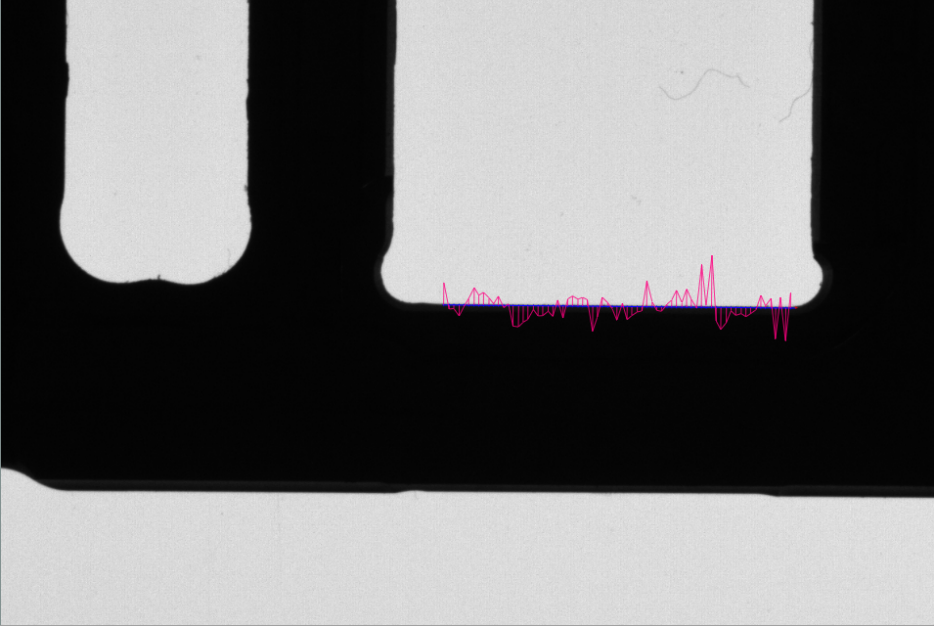

Real-time image display area:

1. Display and preview dynamic or static images from industrial

cameras and zoom freely.

2. Overlay the measuring elements; (Press the middle wheel of the

mouse to achieve shape tolerance after selecting the target)

3. Superimposed display of boundary points;

4. Overlay display element shape tolerance;

The definition of interface display in image display area is

started by menu item, and OK NG can choose display effect for

measurement result.

5. Graphics, CAD editing, measurement report synthesis window:

1. Display switching of image preview area;

2. Dynamic display of measurement elements;

3. Display common tolerance marking;

4. Visual graphic selection elements;

5. Translational Scaling and Selection of Support Graphics

6. Support importing CAD file DXF file format;

7. Support importing Gerber file format;

8. Support export standard DXF file format;

9. Set output options and paths;

10. Built-in measurement report display;

Excel output format; after checking, the real-time data will be

dynamically updated to the table.

6. Report mode: Software can switch report mode freely and click OK

to realize it.