Multifunctional Rapid Vision Measuring System Video Measurement

Machine

Technical parameters:

| Model and parameter | AMO240 |

| Iamge system | 5 million 2/3 inches, 12 million 11.1 inches, 20 million 1 inches

optional |

| Light source | According to the purpose of measurement,optional parallel bottom

light, telecentric bottom light, 1-8 partition ring light, coaxial

light ,etc |

| Repeatability(±μm ) | 2μm |

| Instrument precision(±μm ) | 4μm |

| 100 Element Measuring Time (s) | 0.2s |

| Load-bearing weight(KG) | 20KG |

| Outline dimension(mm) | 450x580x1900 |

The main functions of the software are as follows:

1. Image measurement tools

Specifically, it includes the following functions:

Import static pictures

Import static pictures

Save pictures

Save pictures

Field of view zooming

Field of view zooming

Field of View Adaptation

Field of View Adaptation

Camera Dynamic Preview and Image Capture

Camera Dynamic Preview and Image Capture

Setting of Measuring Parameters

Setting of Measuring Parameters

Point Cloud Tool

Point Cloud Tool

Automatic Recognition of Objects and Spline Curve Circle Measuring

Tool

Automatic Recognition of Objects and Spline Curve Circle Measuring

Tool

Linear measuring tool

Linear measuring tool

Circular measuring tool

Circular measuring tool

Arc measuring tool

Arc measuring tool

Point measuring tool

Point measuring tool

Extremum Measuring Tool

Extremum Measuring Tool

Rectangular Range Definition Tool

Rectangular Range Definition Tool

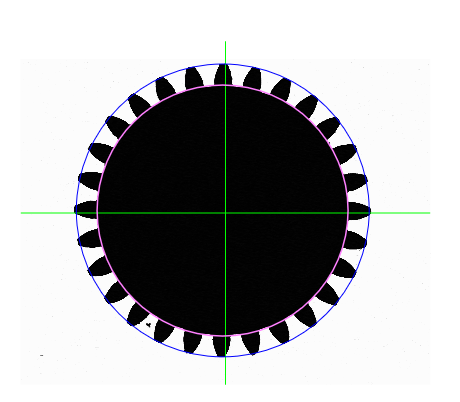

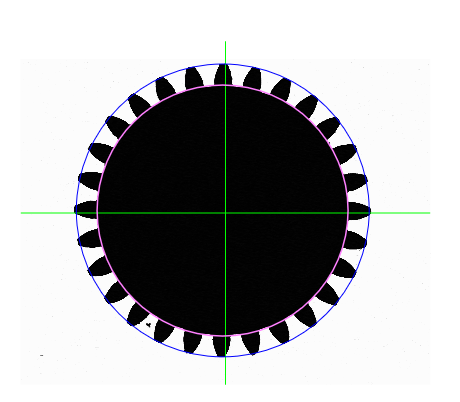

By using the above tools, the measurement of feature elements in

camera shooting or static pictures can be realized. Take the circle

tool as an example, the following is an example of measurement:

concentric circle is the range of edge patrol, which can be

manipulated by mouse to realize the editing functions of zooming,

translating and defining the direction of edge patrol.

Example 1:

Circular measuring tool

Circular measuring tool

Example2

Arc measuring tool

Arc measuring tool

Example3

Linear measuring tool

Linear measuring tool

Example4

Setting parameters of measurement parameters are detailed:

Setting parameters of measurement parameters are detailed:

1.Edge-seeking points: set fixed number of edge-seeking points, or

automatically allocate points according to interval points;

2.Edge Search Range: Search Default Range 30 for Finding Boundary

Points

3.Boundary type: black > white; white > black; step point;

4.Side-finding direction: correctable direction; forward or reverse

direction

5.Extremum type: By setting this value, the special functions of

measuring the maximum outer diameter/minimum inner diameter and

mesh boundary of gears can be realized.

6.Noise filtering: Least squares filtering intensity and Gaussian

pre-filtering method can be set to eliminate measurement noise.

7.Miscellaneous edge location: For the edge with strong

interference noise, three advanced pre-positioning methods are

provided: step gray statistics; dynamic template; static template.

The real boundary can be measured effectively for the noisy edges.

8.Sub-pixel algorithm: According to the characteristics of light

source, sub-pixel compensation parameters can be pre-set to improve

the measurement accuracy;

9.Threshold class parameters: adjustable range of weak edge

measurement and threshold 8BA1 calculation

Example5

Extreme parameter demonstration:

Metering Tool Window

Metrological tools include complete tools for tolerances of 2D

geometric elements and construction operations.

Metering Tool Window

Metrological tools include complete tools for tolerances of 2D

geometric elements and construction operations.

distance tolerance

distance tolerance

Angular tolerance

Angular tolerance

true position

true position

Concentricity tolerance

Concentricity tolerance

perpendicularity

perpendicularity

Parallelism tolerance

Parallelism tolerance

Inclination tolerance

Inclination tolerance

Symmetry tolerance

Symmetry tolerance

Definition of tolerance: Relevant parameters of all tolerances mentioned above can be

defined, such as tolerance name, theoretical value, measured value,

tolerance element, reference element, upper and lower tolerance

zone definition, tolerance calculation type, common algorithm,

material definition, etc.

Example

distance tolerance

Default values are used by default

Type: You can choose to calculate the X.Y axis distance

Element Construction Function: The software adopts a construction

classification method oriented to construction objectives. Through

three clear steps:

1) Selection of one or more geometric elements involved in the

construction

2) Choosing the geometric type of the construction target.

3) Choose the method of construction.

Commonly used construction algorithms include least squares fitting, midpoint, intersection, projection,

parallel plane, vertical, translation, tangency, key point, mirror,

etc., to achieve dozens of different construction algorithms,

covering almost all possible construction types of measurement

software.

Taking the two-level menu of two circles to construct straight

lines as an example, all possible constructions can be obtained as

follows.

The commonly used 2D geometric construction functions are shown in

the following table:

Part coordinate system function:

Part coordinate system function:

The system parts coordinate system can be built iteratively. The

software can build coordinate system intelligently and efficiently

with one key according to the type and position of the elements in

the coordinate system. It can build coordinate system through

point-point class, point-line class, circle-circle class,

circle-line class, line-line class, discrete multi-point fitting,

CAD theoretical element-measured element, B-spline curve. Line

fitting and other methods are used to establish the coordinate

system of parts needed by users.